Cold Heading Die e boetse e bitsoa lefu la ho etsa serame

1. Fektheri ea Machaena e khethehileng ka ho sebetsa le ho hlahisa, setifikeiti sa ISO.

2. Mefuta e mengata ea boholo le mefuta e fumanehang bakeng sa OEM.

3. E entsoe ka 100% ea thepa ea pele ea boleng bo holimo

4. Sehlopha sa tlhahiso ea litsebi, ho fana ka potlako

5. Tšebeletso ea mahala ea setsebi ka mor'a thekiso le tšehetso ea botekgeniki

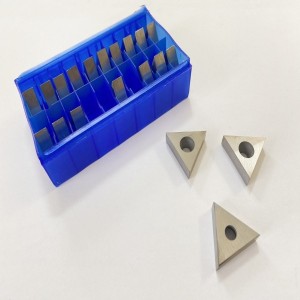

Li-heading tse batang li kenyelletsa mefuta e fapaneng joalo ka li-hole dies, li-triangular dies, extrusion dies, trimming dies, le socket dies.Mokhoa oa ho hatella ho batang, ho nyenyefatsa, kapa ho kenya taper ho khethoa bakeng sa ho kenya carbide ho ipapisitse le ts'ebeliso e itseng kapa litlhoko tsa bareki.Ka mokhoa o ts'oanang, hlooho ea carbide e shoa ka mefuta e fapaneng e kang plain hole, pointing, extrusion, trap extrusion, hexagonal, hex extrusion, flat extrusion, le trilobular ho sebetsana le tlhahiso ea mefuta e sa tšoaneng ea li-fasteners, screws le bolts.

Tse ling tsa lihlahisoa tsa liaparo tseo re li etsang ka tungsten carbide ke:

1. Malebela a Crusher le mehlahare

2. Conveyor scraper blade malebela

3. Li-nozzles tse thunyang, malebela a lerumo, mahare a mabili

4. Tipped static le rotary recycling blades shredding blades

5. Tšusumetso le ho roala lipoleiti

6. Lihamore tsa bar tse shebaneng

RenQiu HengRui Tungsten Carbide e ka etsa ho latela kopo ea hau, hang ha kopo e felletseng le ho taka li ka fanoa.Khanyetso e phahameng ea ho apara le ts'ebetso e tšoarellang e ka finyelloa ka puisano e lekaneng.

Ho bapisa lintho tse bonahalang→ Ho Beha Libolo → Motsoako oa WC le Matla a Cobalt → Ho Tobetsa→ Libōpi tsa HIP Sintering → Ho lemoha QC → Ho paka

Pele ho tlhahiso ea bongata, re hloka ho etsa teko ea ho hatella le ho sintering, 'me re hlahloba ponahalo le boholo, letsoalo le boima ba lisampole tse nang le micrometer, microscope ea Metallurgical, densitometer joalo-joalo ho netefatsa hore litlhoko tsa litšoantšo li ka finyelloa pele ho sehlopha. tlhahiso;Lihlahisoa tsohle li tlameha ho hlahlojoa ka thata ke QC ea rona.

1. Sebelisa 100% tungsten carbide thepa e tala.

2. Lintho tse tsitsitseng tsa lik'hemik'hale

3. Ts'ebetso e ntle haholo le ts'ebetso e ntle ea ho apara / ho senya

4. HIP sintering, compactness e ntle

5. Likheo, ho nepahala / ho nepahala ha machining

6. OEM customized boholo bo fumaneha

7. Tlhahiso ea fektheri

8. Tlhahlobo e tiileng ea boleng ba lihlahisoa

Re tla fana ka thepa e ngata e hlahisoang nakong ea matsatsi a 30 ka mor'a tefo e tlase, ha re ntse re, haeba ho na le likopo tsa soecific ka nako ea ho fana.Re ka etsa phetoho ho latela kopo ea bareki, kahoo nako e khuts'oane ea ho fana e fumaneha ka botlalo.

Hangata 30% T / T esale pele, leka-lekanya 70% T / T pele ho pepa.Hape e ka fetoha ho latela kopo ea bareki.

Re etsa likarolo ka libopeho le boholo bo fapaneng ho lumellana hantle le litlhoko tsa bareki ba rona, hore na ba hloka li-blocks kapa maqephe, li-cylinders, li-bearings, malebela kapa meno.