Li-carbide tse entsoeng ka samente li entsoe ka ho kopanya tungsten carbide le cobalt ka karo-karolelano e itseng, ho hatella ka libopeho tse sa tšoaneng, ebe li-semi-sintering.Mokhoa ona oa sintering hangata o etsoa ka sebōpi sa vacuum.E chesoa ka sebōping sa vacuum mocheso o ka bang likhato tse 1,300 ho isa ho tse 1,500 tsa Celsius.

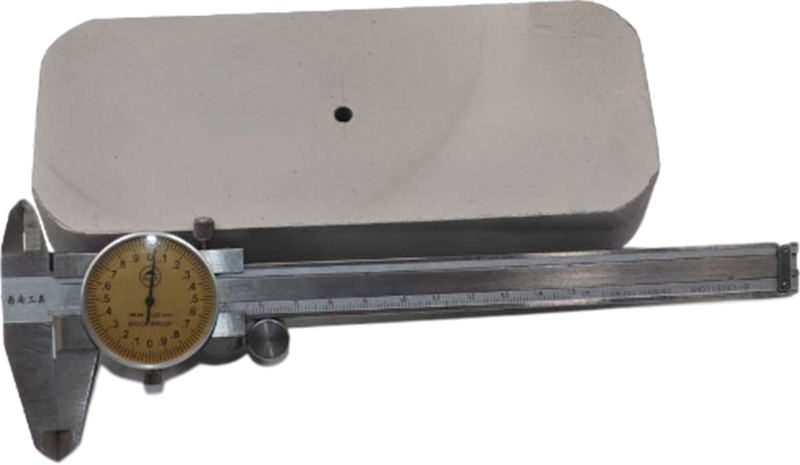

Sebaka se nang le sebopeho se khethehileng

Sintered hard alloy forming ke ho hatella phofo ka har'a billet, ebe ka har'a sebōpi se futhumatsang mocheso ho mocheso o itseng (mocheso oa sintering), le ho boloka nako e itseng (ho tšoara nako), ebe o pholile, e le ho fumana ts'ebetso e hlokahalang. motsoako o thata.

Ts'ebetso ea sintering ea carbide e samente e ka aroloa ka mekhahlelo e mene ea mantlha:

1: Ho tlosoa ha moemeli oa sebopeho le sethala sa ho thunngoa pele, mothating ona 'mele oa sintered o fetoha ka tsela e latelang:

Ho tlosoa ha mochini o bopang, mohatong oa pele oa sintering le ho phahama ha mocheso, mochini o bopang butle-butle oa bola kapa oa fetoha mouoane, o sa kenyelle 'mele o sintered, ka nako e ts'oanang, moemeli oa ho bopa ho feta kapa ka tlase ho 'mele o sintered carburizing, palo ea carburizing e tla fetoha. ka mofuta oa mochini oa ho bopa, palo le ts'ebetso e fapaneng ea sintering.

Li-oxide tsa holim'a phofo li fokotsehile.Ka mocheso o chesang, hydrogen e ka fokotsa li-oxide tsa cobalt le tungsten.Haeba motsoako o tlosoa ka vacuum le sintered, karabelo ea carbon-oksijene ha e matla.Khatello ea ho kopana pakeng tsa likaroloana tsa phofo e tlosoa butle-butle, phofo ea tšepe e tlamang e qala ho hlaphoheloa le ho tsosolosa, ho phatloha ha holim'a metsi ho qala ho etsahala, 'me matla a thibela a ntlafatsoa.

2: sethala se tiileng sa sintering (800 ℃ - mocheso oa eutectic)

Ka mocheso pele ho ponahalo ea mokelikeli, ntle le ho tsoela pele ka ts'ebetso e hlahang sethaleng se fetileng, karabelo e tiileng le ho hasana lia matlafatsoa, phallo ea polasetiki e matlafatsoa, 'me 'mele o sintered o bonahala o fokotseha.

3: Mohato oa sintering oa mokelikeli (mocheso oa eutectic - mocheso oa sintering)

Ha ho e-na le karolo ea mokelikeli 'meleng oa sintered, shrinkage e phethoa ka potlako, ebe phetoho ea crystallization e etsahala, ho theha microstructure ea motheo le sebopeho sa alloy.

4: sethala sa ho pholile (mocheso oa sintering - mocheso oa kamore)

Mothating ona, sebopeho sa microstructure le karolo ea motsoako oa motsoako li fetoha le maemo a fapaneng a pholileng, a ka sebelisoang ho futhumatsa kalafo ea carbide e entsoeng ka samente ho ntlafatsa thepa ea eona ea 'mele le ea mochini.

Nako ea poso: Feb-10-2023