Joalo ka lebitso la carbide ea meno ea indasteri, boholo ba ba e sebelisitseng ha ba tsebe hore na carbide e hlahisoa joang le hore na phapang ke efe ts'ebetsong ea eona ea tlhahiso, ha e le hantle, tlhahiso ea carbide e amana le tšebeliso ea eona ea tikoloho.Ka mohlala, carbide bakeng sa merafo, carbide bakeng sa ho cheka majoe, carbidedisebediswa tsa ho fetola, jj kaofela di itshetlehile hodima tshebediso ya tikoloho.Ho boetse ho na le mohlala, corrosion resistant carbide joalo-joalo.

Cemented Carbide e hlahisoa joang?Mokhoa oa eona oa tlhahiso ke ofe?

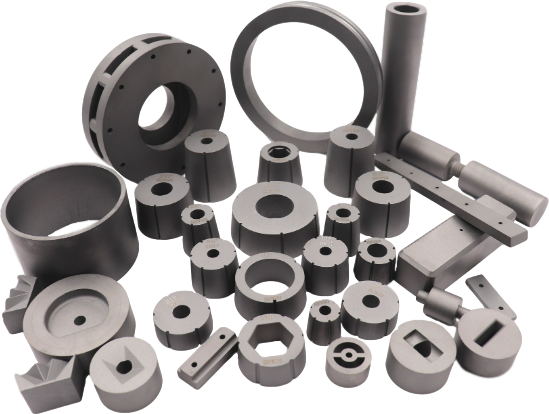

Ts'ebetso ea tlhahiso ea carbide e entsoeng ka samente ka kakaretso e tjena: metsoako e thata ea tšepe (tungsten carbide, tantalum carbide, joalo-joalo), tšepe e kopanyang (cobalt phofo kapa phofo ea nickel) le li-additives tse nyane (stearic acid kapa esomin) fatše ka mokhoa oa ho sila oa hexane, 'me ho eketsoa slurry ea boka ba parafine, ebe ho omisoa ka vacuum (kapa spray omisitsoe), sieved, granulated,' me e entsoe ka lintho tse kopantsoeng;thepa e kopantsoeng e khetholloa ebile e tšoaneleha, 'me ka mor'a ho nepahala Thepa e kopantsoeng e khetholloa ebile e tšoaneleha, ebe e hatelloa ho etsa billet e phahameng ea khatiso;Billet e hatelitsoeng e tšeloa ka vacuum dewaxing kapa sintering ea khatello e tlase ho e etsacarbide e entsoeng ka samente.

Sintering molao-motheo

Ts'ebetso ea "vacuum sintering" e etsoa ka ho futhumatsa tlas'a maemo a vacuum, e leng ho loketseng ho felisa litšila, ho ntlafatsa bohloeki ba sepakapaka sa sintering, ho ntlafatsa mongobo oa mohato oa ho kopanya le ho khothalletsa karabelo.Billet e hatelitsoeng e futhumatsoa moeeng oa vacuum sintering, 'me ha mocheso o phahama' me o fihla mocheso oa mouoane, o tsoa ho billet e hatelitsoeng 'me o tšoaroa nako e lekaneng ka khatello e itseng ea mouoane oa parafine o ka tlaase ho mocheso oo, le parafine. e ntšoa ka har'a billet * e hatisitsoeng ebe e hlaphoheloa, 'me billet e hatisitsoeng ea hloekisoa.Ha mocheso o ntse o eketseha, billet e tlosoa 'me e hloekisoa ka ho eketsehileng,' me ho latela sintering e tiileng.Ts'ebetsong e tiileng ea sintering, liathomo (kapa limolek'hule) tsa karolo e 'ngoe le e' ngoe 'meleng oa sintered lia ata, sebaka sa ho kopana sa likaroloana sea eketseha, sebaka se pakeng tsa likaroloana se fokotseha,' mele oa sintered oa honyela ebe o matlafatsoa le ho feta.Ha mocheso o le haufi le ntlha ea ho qhibiliha ea mohato o tlanngoeng, mohato o kopantsoeng o qala phallo ea polasetiki, 'me ha mocheso oa mokelikeli o fihla,' mele oa sintered o hlahisa mokelikeli oa mokelikeli le mokelikeli oa mokelikeli o hlahang.

Ts'ebetsong ea sintering ea mokelikeli, karolo ea mokelikeli e hlaha holim'a carbide, lecarbidelikaroloana li qhibiliha karolong ea tlamahano ka ho hasana ho theha eutectic, 'me likaroloana tsa carbide li tsosolosa le ho hōla ka boholo ka karolo ea mokelikeli, e le hore likaroloana tse haufi tsa carbide li hokahane,' me 'mele oa sintered o fokotseha ho feta' me o teteaneng ka potlako.'Mele o sintered o tsoela pele ho honyela le ho teteana ka potlako.E tšoaroa ka mocheso o phahameng ho feta mocheso oa sintering oa mohato oa mokelikeli ka nako e itseng e le ho lumella mokhoa oa sintering hore o tsoele pele ka botlalo, ebe o pholile fatše.

Ho pholletsa le ts'ebetso ea sintering, 'mele o sintered o fokotsehile hoo e seng porosity,' me letoto la liphello tsa physicochemical le liphetoho tsa mokhatlo li hlahisoa, e leng se etsang hore ho thehoe carbide e teteaneng, e entsoeng ka samente e nang le lik'hemik'hale tse itseng, thepa ea 'mele le ea mechine, le sebopeho sa mokhatlo.

Nako ea poso: Jun-29-2023