Le hoja ka bobeli tungsten motsoako lecarbide e entsoeng ka samenteKe mofuta oa lihlahisoa tsa alloy tsa transition metal tungsten, ka bobeli li ka sebelisoa sebakeng sa sefofane le ho tsamaisa sefofane le likarolo tse ling, empa ka lebaka la phapang ea likarolo tse ekelitsoeng, karo-karolelano ea tlhahiso le ts'ebetso ea tlhahiso, ts'ebetso le ts'ebeliso ea tsona ka bobeli le tsona li na le kholo e kholo. phapang.

I. Tlhaloso

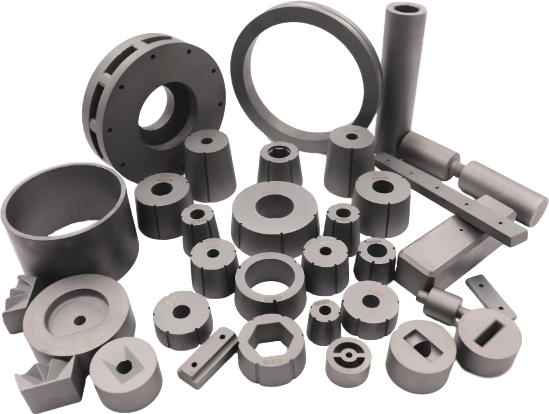

Tungsten alloy, eo hape e tsejoang e le high specific special gravity alloy, ke motsoako o nang le phofo ea tungsten e le eona thepa e ka sehloohong e tala le nickel, tšepe, koporo le likarolo tse ling e le lisebelisoa tse thusang.Litaba tsa tungsten hangata li pakeng tsa 85% le 99%.

Carbide e entsoeng ka samente, e tsejoang hape e le tungsten steel, ke hore, ke motsoako o nang le carbide ea tšepe ea refractory joalo ka tungsten carbide joalo ka motsoako oa mantlha le cobalt, nickel, molybdenum le likarolo tse ling joalo ka setlamo.Litaba tsa binder hangata li pakeng tsa 10% le 20%.

Ea bobeli, ts'ebetso

Alloy e phahameng ea matla a khoheli e na le ntlha e phahameng ea ho qhibiliha, letsoalo, matla le boima, polasetiki e ntle, ho hanyetsa mocheso, ho hanyetsa kutu, ho hanyetsa tšusumetso, ho hanyetsa oxidation le phello ea tšireletso.

Tšepe ea Tungsten e boetse e na le thepa e tšoanang le ea li-alloys tsa tungsten, le hoja ho thatafala ha eona ho futhumatsang le melemo ea ho itoanela ho totobetse haholo, haholo-holo tabeng ea hore e lula e sa fetohe ho 500 ° C 'me e ntse e na le boima bo phahameng ho 1000 ° C.Leha ho le joalo, brittleness ea eona e phahame haholo, kahoo e etsa mosebetsi oa ho itšeha.

Ea boraro, mokhoa oa tlhahiso

Mehato ea ho itokisa ea motsoako oa tungsten: 1) ho lokisetsa lintho tse bonahalang: metsoako ea tungsten e kang ammonium tungstate, lisebelisoa tse thusang tse kang nickel, tšepe, koporo le likarolo tse ling kapa metsoako;2) ho etsa phofo: ho na le mokhoa oa ho omisa le mokhoa oa ho kopanya ka mochini;3) ho theha: ka mor'a ho kopanya phofo ea tungsten le moemeli oa ho etsa, extrusion e kenngoa mochine oa ho etsa, ebe likarolo tse rarahaneng tse nang le sebōpeho li ka lokisoa;4) sintering: ka mor'a ho phekola sintering, mokhatlo o hlophisitsoeng oa motsoako ho feta junifomo le tshebetso akaretsang phahameng tshebetso ka kakaretso.

Mehato ea ho lokisetsa carbide e entsoeng ka samente: 1) Tlosa litšila tse ka holimo tsatungsten carbidelikaroloana le lithollo tsa cobalt;2) Silakanya lisebelisoa tse ka holimo ebe u li kopanya ka har'a motsoako, ebe u li sila ho fumana phofo ea alloy;3) Eketsa phofo ea motsoako ka har'a sesebelisoa sa extrusion ho fumana li-precursors tsa carbide tse samente, ebe u li kopanya le mokelikeli ebe u eketsa binder ho etsa slurry ea phofo ea tšepe;4) Etsa slurry hore e be phofo ka ho fafatsa granulator, ebe u sinter le ho tšoara mocheso.ebe se sintered le ho phekoloa mocheso.

Nako ea poso: Jun-02-2023