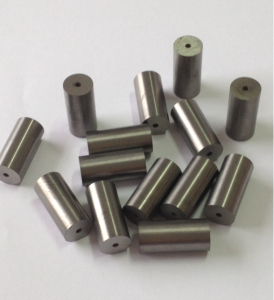

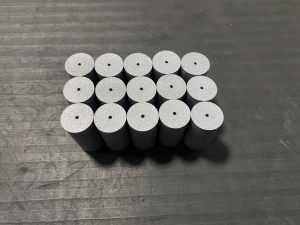

GT40 Cemented Carbide Cold Forging Die YG11 e hanyetsanang le tšusumetso e phahameng

1. E entsoe ke moroetsana thepa e tala.Mohala oa rona oa tlhahiso o romelloa kantle ho naha, nako ea bophelo ba ts'ebeletso ea sehlahisoa e phahame ka 120%.ho otla ka serame ho shoa

2. U se ke ua petsoha.

3. HIP (Hot Isostatic Press) sintering e netefatsa hore microstructure e tsitsitseng, nako ea bophelo ba tšebeletso e telele, phetoho ea lefu e fokotseha, e ka ntlafatsa katleho ea ho sebetsa le ea tlhahiso.

4. Re boetse re fana ka carbide die ka boholo ba lijo-thollo tse mahoashe, tse nang le bokhoni bo phahameng ba ho hanyetsa 'me li ka sebelisoa ho etsa carbide e kholo e shoa.

| Lebitso la Sehlahiswa | tungsten carbide li-pellets tsa lihlooho tse batang |

| Lintho tse bonahalang | Tšepe e thata |

| Boholo | OD55xID24x50 |

| Mamello ea Boholo | Ho latela setšoantšo |

| Mmala | Bohlooho bo botala |

| Khothalletsa Kereiti | G40 |

| Boholo ba lijo-thollo | Boholo ba lijo-thollo tse mahoashe |

| Kopo | screw, linate |

| Ho sebetsa Phekolo | HIP sintering |

| Likarolo tsa Sehlahisoa | Bophelo bo bolelele, apara khanyetso |

| Setifikeiti | ISO9001-2015 |

Litsenyehelo li fokotsehile ka ho eketsa bophelo ba lisebelisoa mme tlhahiso ea ntlafatsoa.

Sekhahla sa sekoli se fokotsehile mme boleng boa ntlafala.

Ho qhetsoha ho hoholo ho thata --------- ho hlaha ha mapetso a tlase

Matla a phahameng le boima-------mamello e ntlafetseng ea petsana

Lithako tse tlase li lekane ------

Ho bapisa lintho tse bonahalang→ Ho Beha Libolo → Motsoako oa WC le Matla a Cobalt → Ho Tobetsa→ Libōpi tsa HIP Sintering → Ho lemoha QC → Ho paka

Pele ho tlhahiso ea bongata, re hloka ho etsa teko ea ho hatella le ho sintering, 'me re hlahloba ponahalo le boholo, letsoalo le boima ba lisampole tse nang le micrometer, microscope ea Metallurgical, densitometer joalo-joalo ho netefatsa hore litlhoko tsa litšoantšo li ka finyelloa pele ho sehlopha. tlhahiso;Lihlahisoa tsohle li tlameha ho hlahlojoa ka thata ke QC ea rona.li-pallets tsa tungsten carbide

1. Re tla leka ka hohle ho araba kopo ea bareki ba rona nakong ea lihora tse 24.

2. Re tla boloka puisano e sebetsang le e sebetsang hantle le bareki ba rona.

3. Re fana ka taolo ea boleng ba boemo ba pele le lits'ebeletso tsa kamora thekiso.

Re tla fana ka thepa e ngata e hlahisoang nakong ea matsatsi a 30 ka mor'a tefo e tlase, ha re ntse re, haeba ho na le likopo tsa soecific ka nako ea ho fana.Re ka etsa phetoho ho latela kopo ea bareki, kahoo nako e khuts'oane ea ho fana e fumaneha ka botlalo.

Hangata 30% T / T esale pele, leka-lekanya 70% khahlanong le T / T pele ho tsoalo.Hape e ka fetoha ho latela kopo ea bareki.

Re etsa likarolo ka libopeho le boholo bo fapaneng ho lumellana hantle le litlhoko tsa bareki ba rona, hore na ba hloka li-blocks kapa maqephe, li-cylinders, li-bearings, malebela kapa meno.