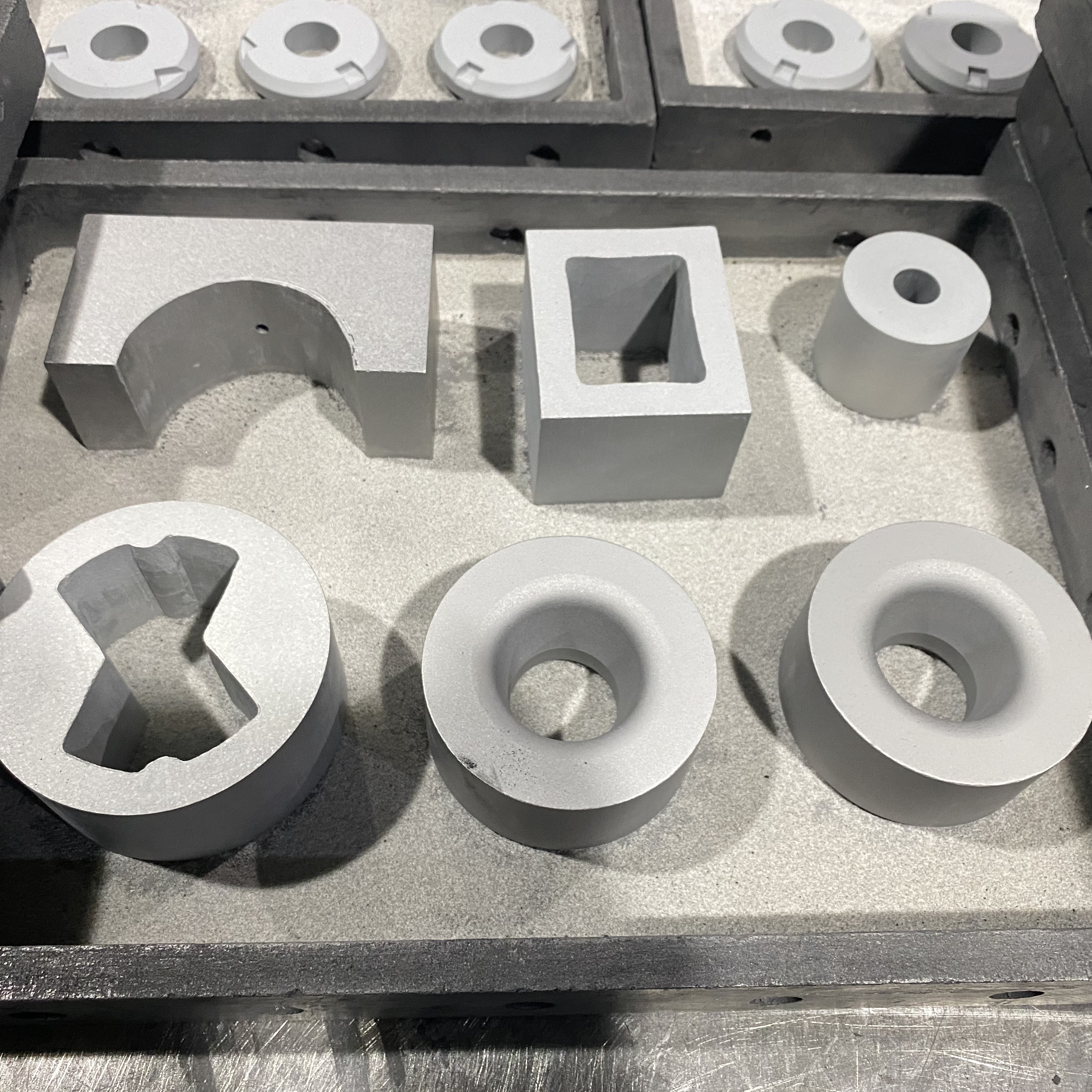

The sintering ofcarbide e entsoeng ka samenteis liquid phase sintering, ke hore, re-bonding phase e boemong ba mokelikeli.Li-billet tse hatelitsoeng li futhumatsoa ho 1350 ° C-1600 ° C ka sebōping sa vacuum.Ho fokotseha ha mohala oa billet e hatelitsoeng nakong ea sintering ke hoo e ka bang 18% 'me ho fokotseha ha molumo ho pota 50%.Boleng bo nepahetseng ba shrinkage bo itšetlehile ka boholo ba karoloana ea phofo le ho hlophisoa ha motsoako.

Sintering eacarbide e entsoeng ka samenteke mokhoa o rarahaneng oa physicochemical process, o kenyelletsang ho tlosoa ha plasticizer, degassing, solid phase sintering, liquid phase sintering, alloying, densification, dissolution precipitation le mekhoa e meng.Billet e hatelitsoeng e siiloe tlas'a maemo a khethehileng ho etsa sehlahisoa se nang le lik'hemik'hale tse itseng, sebopeho, thepa le sebōpeho le boholo.Maemo ana a ts'ebetso a fapana haholo ho latela yuniti ea sintering.

Sintering carbide vacuum sintering ke mokhoa oo sintering e etsoang ka tlase ho 1 atm (1 atm = 101325 Pa).Ho sintering tlas'a maemo a vacuum ho fokotsa haholo tšitiso ea densification ka khase e adsorbed holim'a phofo le khase e ka har'a li-pores tse koetsoeng, tse thusang ts'ebetsong ea ho hasana le ho teteana, ho qoba karabelo pakeng tsa tšepe le likarolo tse ling sepakapakeng nakong ea mocheso. sintering tshebetso, 'me ka haholo ntlafatsa wettability ea mokelikeli viscous mokhahlelo le mokhahlelo o thata, empa vacuum sintering lokela ho ela hloko ho thibela mouoane tahlehelo ea cobalt.Vacuum sintering ka kakaretso e ka aroloa ka mekhahlelo e mene, ke hore, sethala sa ho tlosa polasetiki, sethala sa pre-sintering, sethala sa sintering sa mocheso o phahameng le sethala sa ho pholisa.

Mokhahlelo oa ho tlosa polasetiki o qala ho tloha mocheso oa kamore 'me o nyolohela ho hoo e ka bang 200 ° C.Khase e adsorbed holim'a likaroloana tsa phofo ka billet e arohane le holim'a likaroloana tlas'a ketso ea mocheso 'me e baleha ho tloha billet e sa khaotse.Plasticizer e ka har'a billet e futhumetse 'me e tsoa ho billet.Ho boloka boemo bo phahameng ba vacuum ho thusa ho lokolloa le ho phonyoha ha likhase.Mefuta e fapaneng ea li-plasticizers e na le thepa e fapaneng ha e le tlas'a mocheso, kahoo mokhoa oa ho tlosa polasetiki o lokela ho ntlafatsoa ho ea ka boemo bo itseng.

Ts'ebetso ea ho tlosa polasetiki e lokela ho khethoa ho latela maemo a khethehileng a tlhahlobo.Kakaretso ea mocheso oa polasetiki oa gasification o ka tlase ho 550 ℃.

Sethaleng sa pre-sintering se bua ka mocheso o phahameng oa sintering pele ho sintering, e le hore k'hemik'hale ea oksijene e ka har'a likaroloana tsa phofo le karabelo ea phokotso ea k'habone ho hlahisa khase ea carbon monoxide e siea billet ea khatiso, haeba khase ena e ke ke ea qheleloa ka thoko ha karolo ea mokelikeli e hlaha, e tla fetoha masala a koetsoeng a pore ka alloy, le haeba sintering e hatelloa, ho thata ho e felisa.Ka lehlakoreng le leng, ho ba teng ha oxidation ho tla ama ka botebo ho metsi ha mokelikeli ho ea karolong e thata 'me qetellong ho ama ts'ebetso ea densification ea carbide e entsoeng ka samente.Pele ho hlaha karolo ea mokelikeli, e lokela ho tlosoa ka ho lekaneng 'me ho sebelisoe vacuum e phahameng ka ho fetisisa.

Mocheso oa sintering le nako ea sintering ke mekhoa ea bohlokoa ea ts'ebetso bakeng sa densification ea billet, ho thehoa ha sebopeho se nang le homogeneous le ho fumana thepa e hlokahalang.Mocheso oa sintering le nako ea sintering e itšetlehile ka motsoako oa motsoako, boholo ba phofo, matla a ho sila a motsoako le lintlha tse ling, hape li laoloa ke moralo oa kakaretso oa thepa.

Nako ea poso: Jun-08-2023